by Jay Dunbar, CFSA Local Produce Safety Coordinator

Crops come out of the field with field heat, and removing it quickly is an essential part of good post-harvest handling. Some crops, like leafy greens and root crops, typically undergo wash processes that clean and cool the crops with water. Other crops are cooled using specific hydrocooling methods or ice-cooling, as in commercial broccoli production.

More delicate crops, such as small fruits, cucumbers, and peppers suffer from quality issues when treated with water post-harvest. The added moisture leads to rapid decay. As far as cooling of these crops is concerned, growers often have no choice but to get their harvest refrigerated as soon as possible and let the conditioned air of their coolers slowly bring the crop temps down.

This process is called room cooling. In some cases, produce can take several hours to reach its storage temperature with room cooling. The produce cools unevenly, and the produce in the middle of the storage container is the last to get cooled. As a result, this cooling process can contribute to shrinkage (produce lost to rot and deterioration) and shorten shelf life for some of our most valuable crops.

What Is Forced-Air Cooling?

To reduce this loss and improve the storage quality of high-value crops, consider adding a forced-air cooling system or pre-cooler. Although forced-air technology has been a staple for larger operations dealing in fruits and vegetables for decades, it isn’t often presented as a practical tool for smaller-scale growers. But with a few simple pieces of equipment, almost any grower can add forced-air cooling to their post-harvest process.

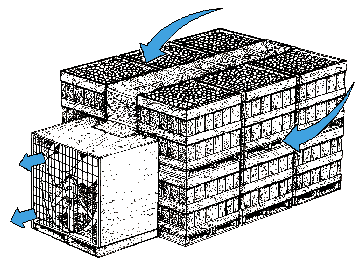

The concept behind forced-air cooling is simple. A fan pulls the cool air of the refrigeration unit through a crate of produce, and this cold, moving air captures heat from the produce as it passes through the crate. The cooling rate depends on the crop, temperature, and airflow, but cooling times are much shorter than room cooling.

A series of trials conducted at the University of Vermont found that forced air cooling rates were 1.2 to 2.2 times faster than room cooling. In addition, forced-air ensures that the produce at the center cools at the same rate as the produce on the sides and top.

One key aspect of these systems is creating the proper airflow. Air, like water, is a fluid that seeks the path of least resistance. Crates need to be packed evenly and adequately ventilated so that the air can get to every piece of produce. Baffles and other methods of directing airflow may need to be incorporated.

Other issues, such as over-chilling and evaporation, should be considered crop-by-crop. In-depth analyses of forced-air cooling can be found at NC State Extension Publications and the University of Vermont Extension Ag Engineering, where designs are also available. As with any post-harvest equipment, you’ll need to test your system and make adjustments to find the best results for your needs.

An infrared thermometer is an excellent tool for testing and monitoring forced-air cooling systems. It can measure the temperature of different surfaces in your system and help you identify cold spots or hot spots. They can be found for under $20 online.

Design Basics

Designs for forced-air coolers vary with the scale of operation and the cooling needs of specific crops. A simple and economical solution for small-scale growers can be seen in this video from UVM:

As you can see, the fan is mounted on a simple wooden housing that sits flush against a pallet stacked with produce crates. The crates are covered on the top, bottom, and sides with a plastic sheet, while the side opposite the fan remains uncovered. With the fan on, the static pressure pulls the plastic up against the crates. Cool air flows from the open end of the stack, through the crates, and then through the back of the fan. In the UVM design, the warm air from the produce vents back into the cooler. Depending on the type of cooler you have, consider venting that warm air out of the cooler.

Another consideration for building a pre-cooler is portability. A farm may have multiple spaces for crop storage and need pre-cooling available in them occasionally. If possible, put that pre-cooler on wheels!

Benefits of Pre-Cooling

A simple, low-budget pre-cooler can positively impact your bottom line. By getting that field heat out more quickly, respiration rates are lower and crops stay crisper. You are left with less shrinkage and more long-lasting, higher-quality vegetables. So whether you are filling CSA boxes and farmers market displays or shipping pallets to distributors, you can rest assured that you deliver the best from your fields.

There are also some food safety advantages to forced-air cooling as it’s an easy way to mitigate post-harvest risks and conform to Good Agricultural Practices (GAP) standards. Forced-air cooling presents fewer microbial contamination risks than either hydrocooling or traditional room cooling.

Because it uses water, hydrocooling requires sanitizers and water quality monitoring. In the hydrocooling process, products must be handled more, and there are typically more food-contact surfaces to consider. These factors contribute to a higher level of food safety concern, GAP requirements, and demand on management.

In the case of room cooling, the temperature and humidity conditions that result from this method can encourage pathogens to spread. Forced-air cooling mitigates these conditions and these risks. After all, properly cooled and stored produce is less likely to rot or deteriorate and is less likely to spread contamination to other produce. Of course, as with any piece of equipment, your pre-cooler will need routine cleaning and sanitation.

Summary

Forced-air cooling is a technology that can be used by small-scale growers to effectively improve the quality and shelf life of high-value fruits and vegetables without adding the burden of extensive infrastructure or additional food safety issues. Although not the perfect tool for every farm or crop, there are plenty of applications for the diverse market and CSA farms that form the backbone of our local food systems. They can also create an advantage for wholesale-oriented growers whose crops need to stay as fresh as possible as they go from farm to distributor to end user.

The CFSA Local Produce Safety Team is here to help improve the quality of your produce and reach new markets. If you live in the Carolinas and would like to discuss forced-air cooling or other strategies for improving post-harvest quality and shelf-life on your farm, let us know. From market access to food safety, our staff can help!