by Tay Fatke, CFSA Local Produce Safety Coordinator

Understanding your strengths and weaknesses is important in any business. For farmers, this includes identifying the risks and understanding hazards of the farm.

A self-audit (or self-assessment) is commonly used by organizations to help evaluate and identify where improvements can be made. Similarly, farms can utilize a self-audit to assist with identifying risks, evaluate current food safety practices — often referred to as mock-audit (or internal-audit) — and is often an annual requirement of Good Agricultural Practices (GAP) certification. If you are not going through an annual GAP audit, or do not have a food safety program currently in place on your farm, no worries! This process benefits farms of all sizes and can be a useful tool in improving your operation.

Food Safety Program vs Food Safety Plan – What’s the Difference?

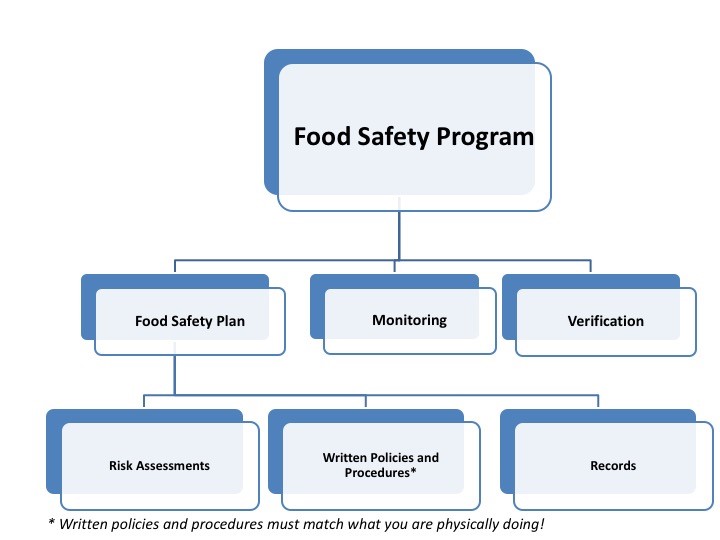

Creating a food safety culture within your organization requires the implementation of a food safety program. There often is confusion between a “food safety program” and a “food safety plan.” The graphic below outlines what encompasses a food safety program.

As you’ll see, a food safety plan is only one component of a food safety program and is made up of written policies and procedures, risk assessments, and records.

As you’ll see, a food safety plan is only one component of a food safety program and is made up of written policies and procedures, risk assessments, and records.

A food safety program also requires creating a food safety culture within your organization. The purpose of the self- audit is to evaluate all components of your food safety program.

The important thing to realize when conducting your self-audit is that the policies and procedures in your food safety plan MUST match what you are physically doing! Anytime the auditor notices a discrepancy in this, they will mark it as a non-compliance and corrective action will be needed. Therefore, don’t be afraid to do the same in a self-audit. A self-audit requires the same follow-up by either matching what the written policy/procedure is or updating the food safety plan to match what you are physically doing, including a corrective action. Again, this must all be in writing.

Can I Conduct a Self-Audit If I Don’t Have a Food Safety Program?

Certainly! While it is recommended that any farm growing produce, even if they are not required to go through a GAP audit by their buyer, establishes a food safety program. We understand that it may take some time to get to that point. Before then, you can still assess your on-farm food safety practices by conducting the self-audit with a few things in mind.

- You may consider utilizing a basic GAP Standard, such as the USDA GAP/GHP Standard and Checklist, often recommended for farms just beginning to develop and implement a food safety program.

- When conducting the self-audit, you may notice you are missing some requirements. Many of the requirements require a Document (D), Record (R), or Policy (P), which without a food safety program in place, it’s unlikely that you are writing information down that would be required.

- You can determine if documentation is required under the “Doc” column on the checklist.

- To assess your operation, based on the requirements that are blank under the “Doc” column, often visual observations relating to on-farm food safety are sufficient in providing a good idea on what improvements can be made within your operation.

Conducting the Self-Audit

The process of completing a self-audit is often easier than people think, as you will use the established USDA Audit Standard and accompanying checklist that your food safety program is built around (Harmonized or GAP/GHP).

If you are using a certification body other than the USDA, you can find the standard and checklist on their website. Every audit is scored a little differently, so the first few pages of each checklist will give you directions on how to complete it. This is the same paperwork the auditor uses when conducting an official audit, which makes the process extremely useful for finding anything during the self-audit that can be corrected before the actual audit date. You can even utilize the self-audit as a reference if you choose to undergo a GAP audit.

As you go through the checklist, be sure to answer everything honestly! It’s better to give yourself a corrective action now using preventive measures than dealing with an incident after it occurs. If you are unsure of how to mark a requirement, be sure to refer to the Standard (Harmonized GAP) or User’s Guide (GAP/GHP), which outlines the procedure, verification, and corrective action for every requirement.

Once you have completed and reviewed the self-audit, be sure to sign and date the front, as this is information your auditor will need to know. Remember, the self-audit is an annual requirement for the GAP audit, but it’s also beneficial to conduct a self-audit anytime there is a change to your food safety program (e.g. hiring a new Food Safety Manager, adding a new packing shed).

Corrective Actions

I’ll say it again, don’t be afraid to give yourself a corrective action! If you are undergoing an audit, the auditor will evaluate your self-audit, but will only ensure that the necessary corrective actions have been made, not resulting in a down score for marking any “Corrective Actions Needed” (CANs) or “NO’s,” so it is perfectly fine to be realistic while conducting self-audit. If you do find an issue when conducting your self-audit, it’s recommended that you conduct the audit a second time. A perfect self-audit will not help you improve your operation.

Someone’s meal sitting on draining board of 3-bay salad greens sink

When a corrective action is made, it is recommended that this process is documented, however, it may not be a requirement of the GAP Standard (depending on the type and significance of the non-conformance). A corrective action that results in a simple policy change may not need to be documented as such, but an observation during the self-audit – perhaps an employee wearing dirty clothes – would require a documented corrective action. In this case, this would warrant filling out a Notice of Unusual Occurrence and Corrective Action (NUOCA) Form.

- Risk identified: The potential of cross-contamination to the product.

- Source: the dirty clothes.

Examples of corrective actions:

- Require the employee to wear protective clothing for the rest of the workday to cover the dirty clothes.

- Best practice: Retrain the employee on the clean clothes policy.

Use the Self-Audit to Your Advantage

During an official audit, the auditor must make a note every time they mark a requirement “Not Applicable” (N/A), “Corrective Action Needed” (CAN) or “NO,” depending on the audit standard, to provide the reviewers with an explanation for scoring decisions. It is worth your time to do the same for multiple reasons.

- First, this challenges you on why you think it’s N/A or non-compliant. When completing your audit, you may mark a question pertaining to washing produce in the field “N/A” because you field-pack all product immediately after harvest. This question would require a comment that “All products are field-packed, and we do not wash products in the field.”

- Secondly, two people may disagree on scoring. Let’s say you believe a requirement should be “N/A”, but the auditor marked it as non-compliant. Upon referencing your self-audit notes, you can be more confident when articulating the reasoning for believing the requirement is not applicable to your operation.

- Finally, another great use of the self-audit is to familiarize yourself with the content of your program and be able to quickly reference your food safety plan when asked a question. You may find it helpful to write down the page number and section of each written policy that is a requirement on the audit checklist, allowing you the ability to quickly tell the auditor what page of the food safety plan addresses the topic.

You’re Not Alone!

The process of conducting your first self-audit can be tedious, but it is important that you realize you are not alone!

The Carolina Farm Stewardship Association, through the Local Produce Safety Initiative, can assist in implementing a personalized food safety program, conducting a self-audit, and getting audit ready! These FREE consulting services are available to CFSA members.

Questions?

Contact the Local Produce Safety Initiative staff at CFSA:

- Tay Fatke, Local Produce Safety Coordinator – tay@carolinafarmstewards.org

- Trish Tripp, Local Produce Safety Manager – trish@carolinafarmstewards.org