Raising poultry for eggs is common for many small farms and homeowners. Adding egg layers to your farm can be a profitable way to diversify your farm business, or you may just raise eggs for your own use. In either case, egg producers need to know how to safely handle poultry and eggs to minimize the risks of foodborne illness. If you sell eggs, you also need to know the laws and regulations that apply to your operation.

Poultry and eggs can carry Salmonella, a bacterial pathogen that can cause illness and even death in people. Common symptoms of salmonellosis include diarrhea, fever, and abdominal cramps, usually within 12 to 72 hours of ingesting the bacteria. Salmonella can be found on, and even in, raw shell eggs, as well in poultry fecal material. It is transmitted to humans when they consume undercooked contaminated eggs or anything else that may be contaminated with the bacteria.

According to the CDC, a Salmonella outbreak has been linked to backyard poultry every year for at least the last decade. In addition, a few multistate outbreaks have been linked directly to shell eggs. As an egg producer, it is important that you know how to safely manage poultry and handle and store eggs to reduce the risk of spreading Salmonella. In addition, eggs are also classified as one of the top nine food allergens in the United States, and farmers who raise eggs and other products must implement practices to reduce cross-contact.

Poultry health and housing best practices.

Managing Salmonella on the farm starts with good poultry health and hygiene.

- Purchase chicks from a hatchery participating in USDA’s National Poultry Improvement Plan voluntary Salmonella monitoring program.

- Maintain flock health by providing clean water and a nutritious diet.

- Monitor flock health and only use approved flock medications. Consult a veterinarian or a Cooperative Extension Poultry Specialist for more information.

- To reduce Salmonella and other health risks in your poultry housing, a complete dry cleaning, washing, and disinfection of the poultry house after each flock or at least once a year is recommended.

- Keep rodents out of poultry housing and feed storage areas. Rodents can also carry Salmonella and can be a source of contamination in your operation.

Minimizing cross-contamination on the farm.

Diversified farms that produce eggs along with fruits, vegetables, and herbs especially need to implement practices to minimize the risks of cross-contamination. Below are some ways to reduce the likelihood that your produce inadvertently becomes contaminated with Salmonella.

- Have separate shoes or boots for working with poultry.

- Change clothes between poultry and produce activities.

- Wash hands after working with poultry or handling eggs.

- Clean and sanitize any equipment or tools between uses that are used in both poultry and produce operations.

- Think about how you store used poultry litter and manure. Make sure it will not contaminate your water sources or produce growing and handling areas.

- If you have ventilation fans in your poultry housing, ensure they are not blowing onto growing crops, open water sources, or packing areas.

- If you use poultry manure as a fertilizer source, either compost it using a method that is known to kill human pathogens or apply it following the National Organic Program guidelines for using raw manure [90 days between application and harvest for crops that do not come into contact with the ground (like tree fruits, trellised tomatoes, blueberries, etc.), 120 days between application and harvest for crops that do come into contact with the ground (most leafy greens, melons, strawberries, etc.) ].

- To reduce allergen contamination of produce or other farm products by eggs, it is important to have separate areas for cleaning and storing eggs. Eggs should also be kept separate during transportation, and any coolers used for transporting eggs should be labeled “eggs only” or cleaned and sanitized before using other products.

Safe handling practices for eggs

Egg collection

- Eggs should be collected frequently; twice a day is recommended. This helps keep eggs clean. Once collected, eggs should be kept at 60° F or below until cleaned and packed.

- Worker health and hygiene is important. Anyone handling eggs or egg contact surfaces should wash their hands. Sick workers should not be in production areas as they may transfer other pathogens to the eggs or food contact surfaces.

- Egg collection containers should be cleaned and sanitized regularly.

Egg cleaning facilities

Areas where you clean, pack, and hold eggs should be maintained so that they do not become a source of contamination.

- Any surfaces with which eggs and packaging materials come into contact should be easy to clean and sanitize. This could be a plastic, laminate, stainless steel table or countertop. Wood surfaces can be cleaned but are difficult to sanitize properly and should be avoided.

- Sanitizers should be labeled for use on food-contact surfaces and should only be used at the recommended concentration found on the label. Common sanitizers include germicidal bleach and Sanidate 5.0 (active ingredients hydrogen peroxide and peracetic acid). These sanitizers are also approved for use directly on shell eggs.

- Good lighting is important so you can thoroughly inspect eggs for cleanliness and defects.

- Monitor areas for pests (rodents, insects, birds, etc.) and use pest control methods if needed.

- Keep domestic animals out of areas where you handle eggs and store egg cartons.

Egg cleaning methods

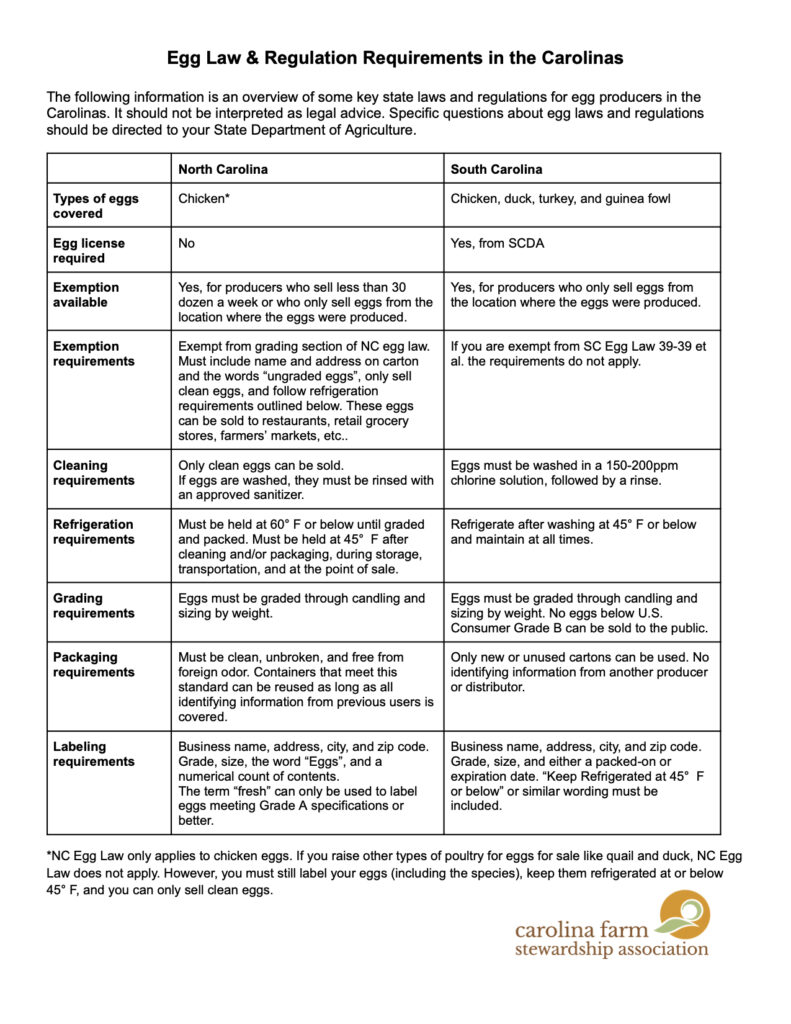

Egg cleaning requirements differ depending on your state (see table below). Regardless of your state, you cannot sell dirty eggs, and you should follow these practices to minimize food safety risks. Even if you are producing eggs for your own use, following these cleaning recommendations is a good idea to reduce food safety risks.

Floor eggs or very dirty eggs should not be sold.

If eggs are lightly soiled, clean them using one of the two methods below. The cleaning process removes the egg’s natural protective coat, which is the main reason why eggs must be sanitized after cleaning if you are selling eggs.

- Dry cleaning: lightly soiled eggs can be cleaned using a piece of sandpaper.

- Wet cleaning or washing:

- Water used in washing must be drinking water quality. If you use well water, have it tested at least once a year.

- Wash water temperature should be 20°F warmer than the egg temperature (at least 90°F). Because eggshells are porous, washing with cold water will draw any contamination in the wash water or on the egg’s surface into the egg. It may seem counterintuitive, but do not wash your eggs with cold water.

- Detergents can be used as part of the cleaning process but are not always required.

- If you do use a detergent, rinse with clean running water.

- Rinse with a sanitizer (100-200 ppm chlorine) or other approved sanitizer. Organic producers should check with their certifier. You may need to rinse the eggs again after sanitizing to remove any sanitizer residue.

- Dry your eggs before packaging.

- Make sure cleaning and sanitizing products are labeled for use in egg washing. Eggshells are porous, so cleaning and sanitizing agents can be absorbed into the eggs. The FDA regulates compounds that wash and sanitize eggs as potential food additives.

- Do not submerge eggs in water as this may create a vacuum that draws contaminates into the eggs through the shell.

Packaging and labeling

Clean eggs should be dry before packaging. Only clean cartons or flats should be used. Packaging and labeling requirements vary by state (see table).

Refrigeration

Egg quality deteriorates quickly when eggs are not refrigerated, especially once they have been washed. A 2018 study evaluating the impact of refrigeration on egg quality for washed and unwashed eggs found that eggs stored at room temperature (71.6° F) deteriorated more in one day than eggs stored at 39.2° F did in 15 weeks. Clearly, refrigeration is important for maintaining quality, and it is an important food safety practice. See the table below for egg refrigeration requirements in the Carolinas.

- As mentioned above, eggs should be stored at 60° F or below after collection. To maintain quality, it is recommended that you clean and pack them as quickly as possible. Once cleaned and/or packaged, they must be kept at 45° F or below during storage, transportation, and at the point of sale. Small farms can use a dedicated refrigerator for storing eggs or have a separate shelf in a walk-in cooler just for eggs.

- You do not have to have a refrigerated vehicle to transport eggs. If eggs are pre-cooled before transport, you can put them in a cooler. It is a good idea to check whether they maintain the correct temperature during transit using a thermometer. If not, you can use ice packs or invest in a plug-in cooler to keep the eggs cold.

- Egg cartons need to be kept dry, so don’t use loose ice, and if you have issues with condensation from ice packs, you may want to put a barrier between the eggs and the ice pack.

- Keeping eggs cold can be challenging for producers selling eggs at farmers’ markets. You want to tell customers you have eggs but must keep them at 45° F or below. Eggs to be sold should be kept in a cooler, not on your table for display. Some ideas for creative marketing include stacking empty cartons on your table, having a ‘sacrificial’ carton of eggs just for display, and displaying pictures of your eggs and farm.

If you sell eggs, it’s important to understand and follow the rules and regulations that apply to your operation. This information is an overview of some key laws and regulations for egg producers in the Carolinas. It should not be interpreted as legal advice. Specific questions about egg laws and regulations should be directed to your State Department of Agriculture.

Need further information or guidance?

- CFSA is here for you! Reach out to our Farm Services team today.

- Egg Law & Regulation Requirements in the Carolinas

- NC Egg Law and Regulations

- 7 CFR § 56.76 – Minimum facility and operating requirements for shell egg grading and packing plants.

- SC Egg License Quick Guide

- A Dozen Egg Abnormalities: How They Affect Egg Quality Publication from University of Georgia Extension

- How Other Countries Handle Egg Storage

- How to Sell Shell Eggs Into Grocery Stores Through Direct Store Delivery NC State Extension Publication

- Explaining the North Carolina Egg Law for Producers with Small Flocks NC State Extension Publication

About the Author

Sara Runkel is CFSA’s local food program director, which oversees CFSA’s Food Safety assistance programs—including GAP certification, FarmsSHARE, and market access.

Sara is passionate about creating sustainable food systems and is committed to helping farmers manage risk to be environmentally, socially, and economically sustainable. She is a lead trainer with the Produce Safety Alliance and has worked with growers on produce safety issues since 2010.